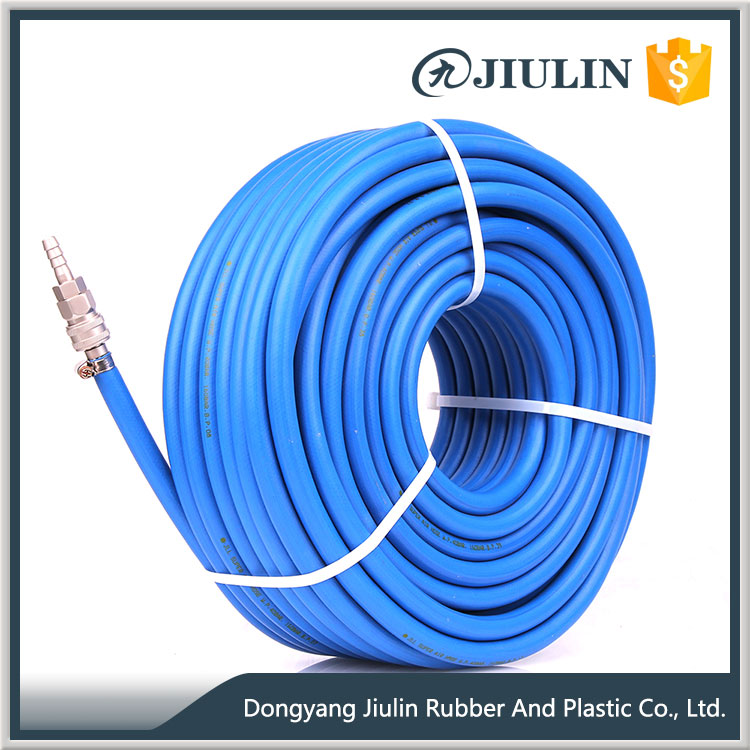

Pneumatic hose to adapt to the range

Assembly of all kinds of pneumatic tools, pneumatic automation machinery, air compressors and various types of connecting pneumatic components.

Performance parameters

Wear resistance: 30mg

Limit extension rate: 390-480% burst pressure: 20-30kgf / cm2

Working vacuum: -25hg60-15kgf / cm2

Tensile strength: 300kgf / cm2

Burst pressure and long-term use of pressure safety factor ratio of 3: 1

Tip: Polyurethane pneumatic hose for compressed air, general industrial water, non-corrosive oils. For long-term service life, it must be used under rated working pressure and ambient temperature. As the temperature rises, the working pressure should be reduced accordingly, and if the limit is exceeded, the hose may rupture. The chemical costs of high fluid temperatures or corrosive fluids can cause hose ruptures, excessive service temperatures, or chemical gases in the workspace, which can cause hose cracking, storage in wet areas, or over-storage Long, will make the hose hydrolysis or aging, may lead to fracture phenomenon